How to Choose the Right Micron Rating for Pleated Filter Cartridges

Learn how micron ratings impact filtration performance. Explore industry-specific micron ranges and practical methods to choose the right filter.

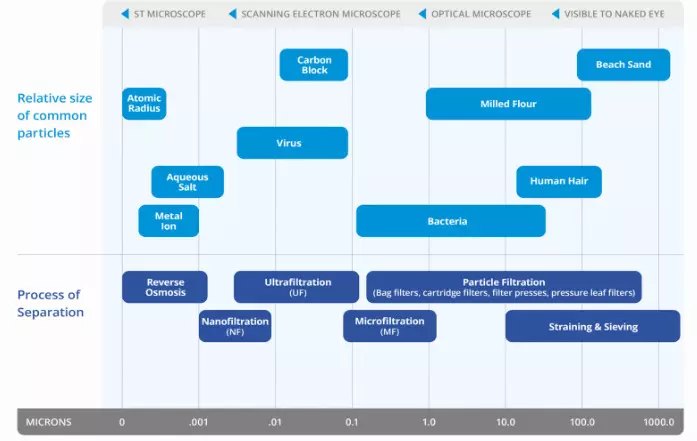

image for illustrative purpose

Introduction of Micron Ratings

When evaluating pleated filter cartridges for your system, one of the first questions you’ll encounter is “What micron rating do I need?” This is not a cosmetic detail on a datasheet — it directly affects how well the filter performs, how often it needs to be replaced, and ultimately how your entire process operates.

Before we jump into numbers and recommendations, let’s start with the basics.

What Does “Micron Rating” Really Mean?

A micron (µm) is one-millionth of a meter — an extremely small unit used to describe particle size. When a filter is assigned a micron rating, it indicates the approximate size of particles that the filter is designed to remove from a fluid stream.

For example:

A 5-micron filter is designed to block particles of about 5 µm or larger.

A 1-micron filter captures much finer particles, including many bacteria and colloidal solids.

To put this in perspective, a human hair is generally about 40–90 microns in diameter — meaning even a 10-micron filter removes particles invisible to the naked eye.

Why Micron Ratings Matter

The micron rating you choose affects three key performance areas:

1. Filtration Performance

The smaller the micron rating, the more solid particles are removed from your fluid. This helps protect downstream components like pumps, membranes, or heat exchangers.

2. Differential Pressure & Service Life

Finer filters clog sooner. As contaminants build up on the media, pressure drop increases and flow rates fall — meaning filters must be changed more frequently.

3. Operating Cost

Choosing an overly fine filter can unnecessarily shorten service life and raise replacement costs. Conversely, a filter that’s too coarse may fail to protect critical downstream components.

Nominal vs Absolute Ratings: What’s the Difference?

One of the most misunderstood concepts in filtration is the difference between nominal and absolute ratings.

Nominal Rating

A nominal micron rating indicates that a filter will remove a majority of particles at that size — typically in the range of 60%–98% efficiency depending on media type. These filters are often used for prefiltration or general protection stages where perfect retention isn’t required.

Example:

A nominal 10-micron filter might remove ~90% of particles 10 microns and larger, but some particles of that size will still get through.

Absolute Rating

An absolute rating means the filter is engineered to remove virtually all particles at or above a specific micron size — commonly understood as 99.9% or greater efficiency in controlled testing. These are typically used in critical applications where contaminant breakthrough cannot be tolerated (e.g., final filtration before product line entry).

Put simply:

Absolute = stringent control, high retention, often higher cost.

Nominal = broader range, lower cost, suitable for early stage filtration.

How to Choose the Right Micron Rating

Selecting the right micron rating is not about choosing the smallest possible pore size, but about aligning the filter performance with your specific process requirements. An incorrect micron rating can lead to excessive pressure drop, shortened service life, or inadequate contaminant removal.

To avoid these issues, it is essential to understand how to choose the right micron rating for pleated filter cartridges based on application, fluid characteristics, and system design.

Step 1 — Define Your Filtration Objective

Are you protecting downstream equipment, meeting regulatory quality standards, or achieving final product clarity?

Your answer determines whether a nominal or absolute filter is appropriate.

Step 2 — Understand Your Feed Quality

High sediment loads benefit from staged filtration — coarser filters first to remove large debris, followed by finer filters to polish the fluid.

Step 3 — Balance Flow and Dirt Holding Capacity

Finer micron ratings capture more contaminants but fill up faster. Consider the trade-offs between service life and filtration demands.

Typical Micron Ratings and Applications

Below are common micron ranges and where they’re typically used:

Micron Rating Typical Use Cases

0.2–1 µm Sterile filtration, pharmaceutical, final drinking water polishing

1–5 µm Protecting membrane systems like RO, fine particulate removal

5–10 µm General industrial prefiltration, food & beverage processes

10–50+ µm Large debris removal, protecting pumps and valves

Use this as a starting point, then refine based on your actual fluid quality and system demands.

While general micron ranges provide a useful starting point, many industries have well-established filtration practices based on years of operating experience. The table below summarizes typical micron ratings commonly used in different applications, reflecting real-world performance requirements rather than theoretical limits.

This reference is especially useful during early-stage system design or when reviewing existing filtration setups.

Application Typical Micron Ratings

Beverage Packaging 0.2, 0.45 & 0.65 μm (spoilage organism control); 1.0 μm (prefiltration); 5.0 μm (clarity and brightness)

Spirits Filtration 5.0 μm (clarity and brightness); carbon filtration for colour and flavour adjustment

Building Services 5.0 μm or 10.0 μm (sediments, pipework debris)

Process Water 0.2 μm (sterile filtration); 1.0 μm (prefiltration); 5.0 or 10.0 μm (guard or trap filtration)

Compressed Air 0.2 μm (sterile air); 1.0 μm (prefiltration, oil and water removal)

Chemicals & Solvents 0.2 μm (sterile filtration); 1.0 μm (carbon removal); 5.0 μm (prefiltration)

Brewing 10 μm or 5.0 μm (clarity and brightness); 0.45 μm (spoilage organism removal)

Municipal Water 5.0 μm (turbidity reduction); 1.0 μm (cryptosporidium control); 10 μm (RO protection)

Coatings, Inks & Paints 1, 5, or 10 μm (solvent-based systems); 0.2–0.45 μm (water-based systems)

Soft Drinks 25–35 μm (syrup filtration); 10 μm (incoming water); 5 μm (bottling stage)

Parts Washing & Equipment 1, 5, or 10 μm (particulate removal); carbon filtration for organic impurities

Practical Tips from the Field

Here are a few pointers recommended by filtration specialists:

Start with coarser filtration: In high sediment environments, begin with a 20–50 µm filter before moving to finer ratings.

Don’t ignore efficiency ratings: High efficiency nominal filters can outperform poorly constructed absolute filters.

Monitor pressure drop: A rising differential pressure is often the earliest sign that a filter needs replacing.

Practical Methods for Selecting the Right Micron Rating

In practice, selecting the right micron rating is rarely based on theory alone. Most filtration decisions rely on a combination of testing, operational experience, and supplier input. The following methods are commonly used in real projects.

Small-Scale Trials

Pilot testing allows engineers to evaluate filter performance under actual operating conditions. By observing pressure drop, flow stability, and service life, users can quickly identify whether a selected micron rating is too fine or too coarse for the application.

Particle Analysis

Laboratory analysis of fluid samples helps determine particle size distribution and contaminant concentration. This method is particularly useful for high-value processes where filtration failure carries significant cost or quality risk.

Historical Data and Industry Experience

For many users, the most practical approach is to rely on previous operating experience or established industry standards. Equipment suppliers and filtration manufacturers often provide valuable guidance based on similar applications already in operation.

In most cases, a combination of historical data and supplier expertise offers the best balance between reliability, cost control, and implementation speed—especially when time or testing resources are limited.

Conclusion

Understanding micron ratings — and how they relate to performance and cost — is essential for designing a reliable filtration system. The right micron rating ensures your system runs efficiently, minimizes downtime, and delivers consistent quality output.

If you’re unsure which micron rating best fits your application, consider talking with filtration specialists who can review your process data and recommend the optimal solution.